Our accessible Organ on a chip technology recapitulates human organs and meets your everyday practical needs

Our design philosophy focuses on enabling you to recreate the most predictive in vitro models with ease.

Originally launched in 2018, our PhysioMimix® Organ-on-a chip technology was commercialized from the “Legacy” prototype developed by Professor Linda Griffith’s pioneering laboratory at the Department of Biological Engineering, MIT. Since then, the technology has constantly evolved from 10+ years of know-how with single, multi-organ and higher throughput options now available. PhysioMimix’s enhanced performance over traditional approaches, robustness and reliability are FDA-recognized, and the technology has supported a successful regulatory filing for metabolic liver disease.

In my experience, you don’t need any specialized skills beyond standard tissue culture. The PhysioMimix system is now very much a plug-and-play instrument. When I started, the legacy liver chip required more manual construction, but now everything arrives ready to use. As long as you know how to maintain sterile tissue culture, you’re good to go!

Amanda Clark, Ph.D.

Research Assistant Professor, Department of Pathology, University of Pittsburgh

2D v 3D

Traditionally, the equipment, workflows, and methods used for drug testing are optimized for 2-dimensional cell cultures on flat microplate surfaces…

…but human biology is not flat!

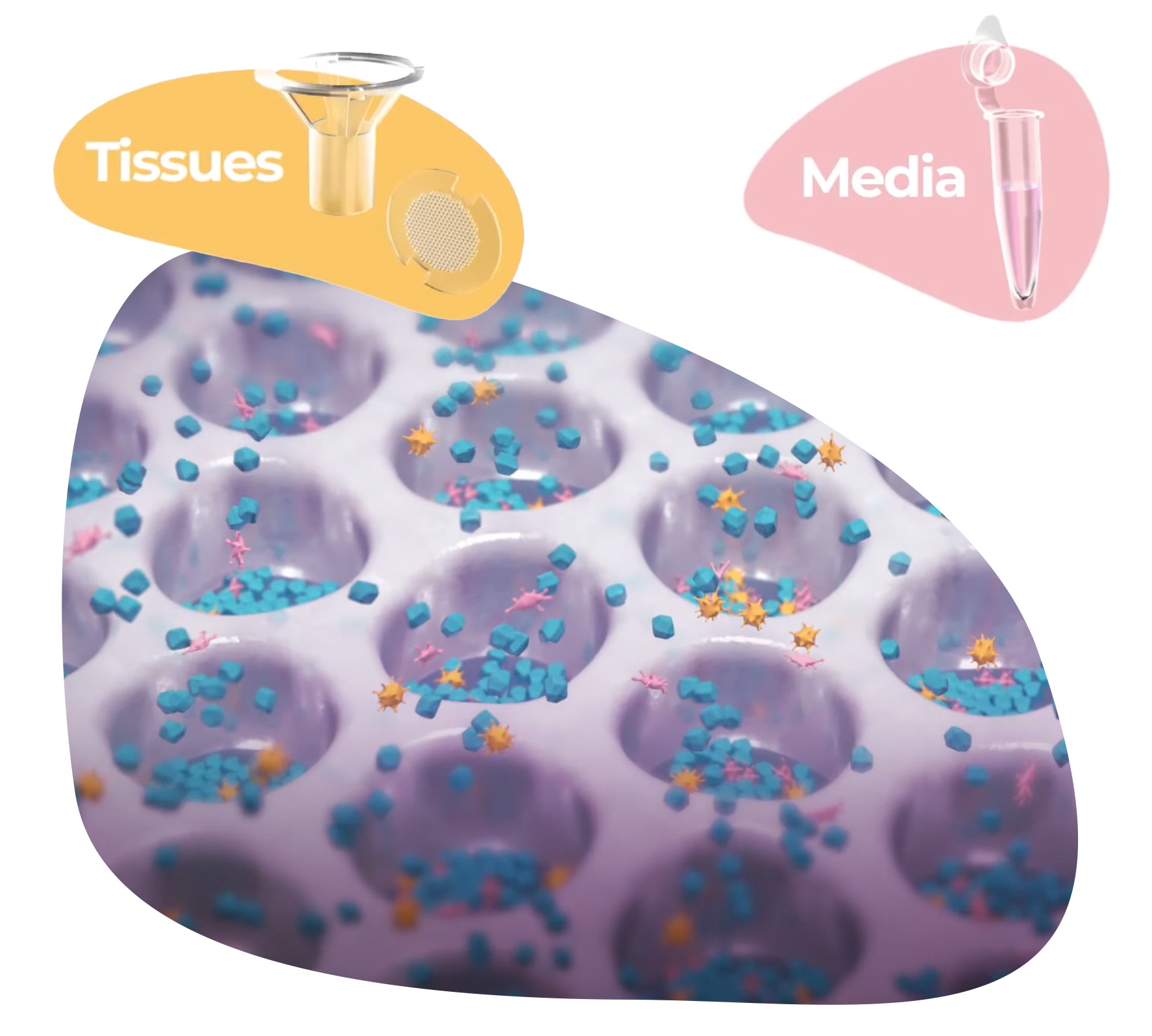

Organ-on-a-chip (OOC) technology, also known as microphysiological systems (MPS), generate 3-dimensional organ and tissue mimics that are perfused by fluidic flow to recreate the bloodstream.

PhysioMimix development

What drives PhysioMimix Organ-on-a-chip technology development?

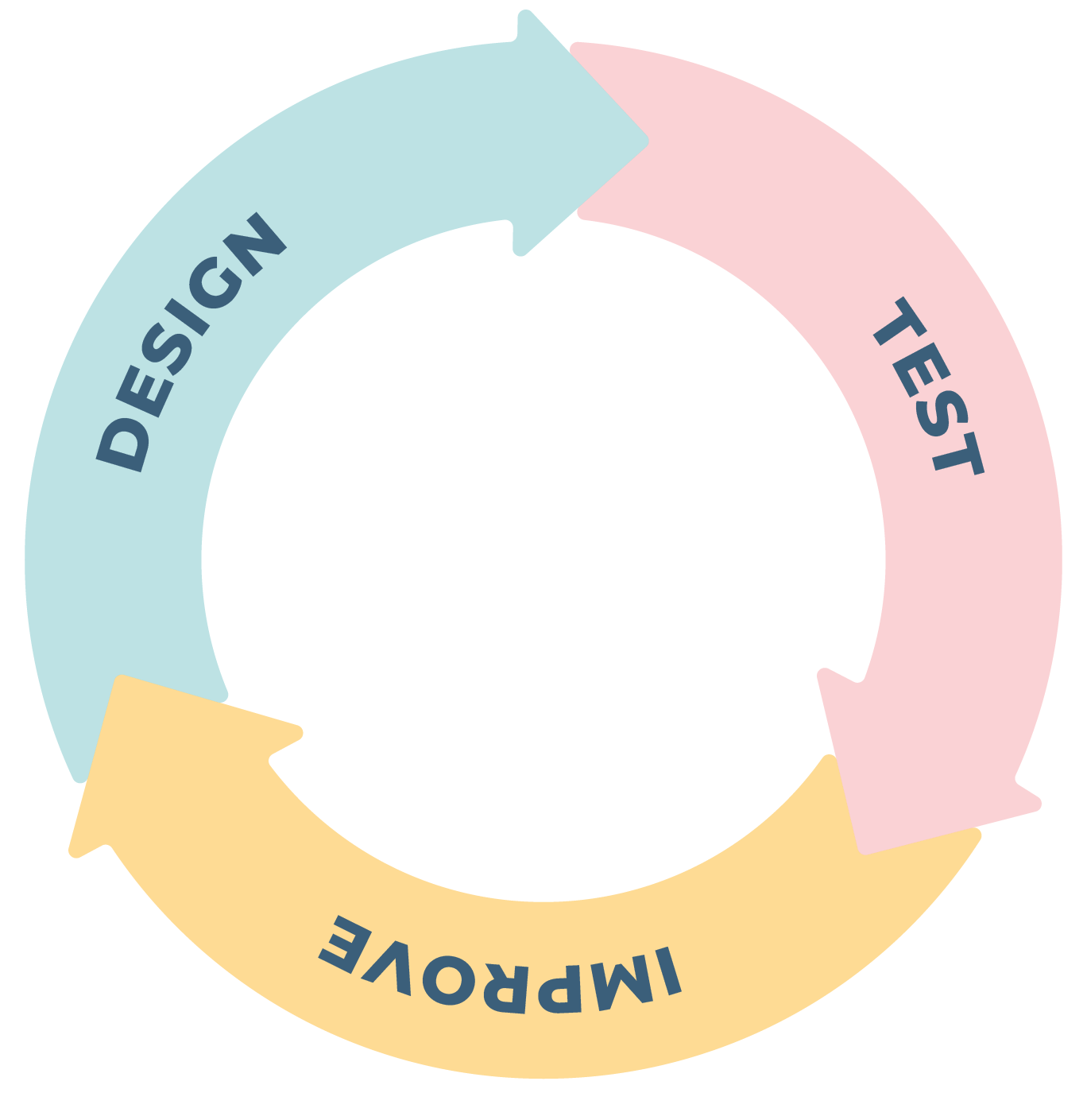

Our product pipeline is driven by market demand, developed through precision engineering, and rigorously tested to deliver scientific excellence. We perform market research to identify customer requirements and specifications. From here, our Science and Technology teams utilize a cyclical design, test, and improve process to deliver a final solution that meets your needs.

Read the following poster outlining the development of our new Multi-chip Liver-48 plate to learn more about our development process.

Why is PhysioMimix Organ on a chip technology like no other?

It’s easy to adopt, adapt and scale to meet current and future needs!

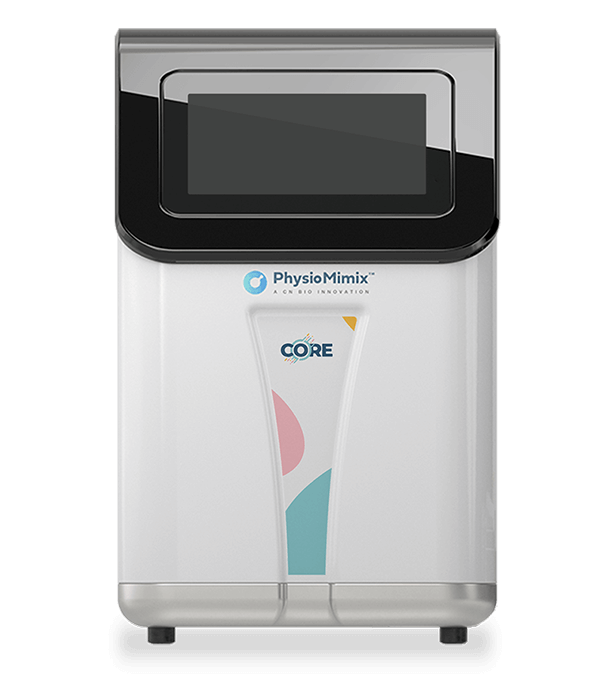

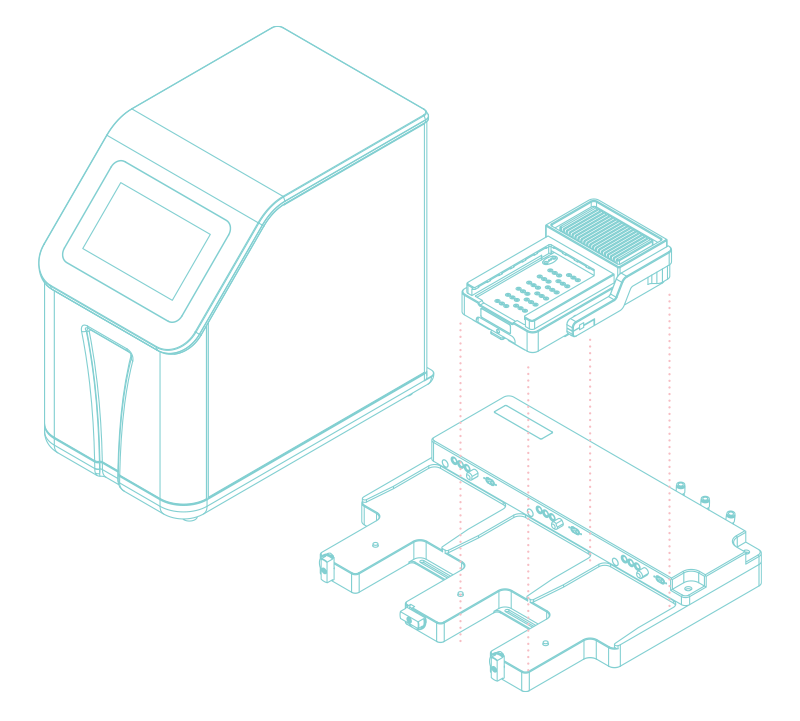

1. Compact benchtop systems

The best things come in small packages

Laboratory space is always limited, so our PhysioMimix Core System feature a compact, benchtop design with the potential to stack multiple Controllers on shelving units where space is at a premium.

Our Organ-on-a-chip technology is simple to install and integrate into existing laboratory workflows. Installation takes around one hour. The System’s Docking Station fits neatly into the shelf of a standard incubator and is connected via a side or rear access port to the Controller. No external compressed air supply is required.

Download our OOC-ready equipment guide to see what you require in your laboratory to get started.

PhysioMimix Core laboratory set up

Visualize how easy it is to adopt and integrate our Organ-on-a-chip technology into your laboratory

2. Precise and controllable flow perfusion

Enhanced functionality and longevity

Fluidic flow recreates physiological exposure to nutrient exchange, re-oxygenation, and shear stresses to optimize organ functionality and extend culture viability up to one month.

Many pumps in commercially available OOC systems produce pulsatile flow only – which is great if you want to make an artery. However, when modeling other organs, such as the liver, consistent flow velocity and shear stress are desired; therefore, PhysioMimix Organ-on-a-chip technology utilizes a proprietary dampener to provide configurable fluidic flow.

Each well within a Multi-chip plate contains integrated fluid pumps to mimic blood flow. This means that no daily cleaning and maintenance routines are required.

Flow rates can be modified by the user. For Dual-organ plates, the flow rate between each organ’s compartment can also be precisely controlled to mimic inter-organ connectivity as provided by the bloodstream.

Importantly, PhysioMimix utilises closed-loop fluidics that recirculate media around cultured microtissues, as opposed to single-pass fluidics. This approach ensures that secreted biomarkers are not diluted in an outlet reservoir for easier detection. Plus, it enables the inclusion of circulating immune cells to understand their interactions with organs, the generation of an inflammatory response to stimuli or drugs, including monoclonal antibodies, and the study of inter-organ inflammatory crosstalk.

3. High-content mechanistic insights

When size matters

The larger-scale microtissues cultured in our Multi-chip plates (compared to micro-scale chips) provide high functionality (e.g. metabolic capacity) and assay sensitivity.

More concentrated volumes of media (~ 1 mL) can be sampled over time or at the end of an experiment to enable the quantification of a wider number of clinically relevant biomarkers or metabolites/ test for deep mechanistic insights.

Scaffolds and inserts can easily be removed from plates, enabling microtissue recovery for additional -omics and microscopy analysis.

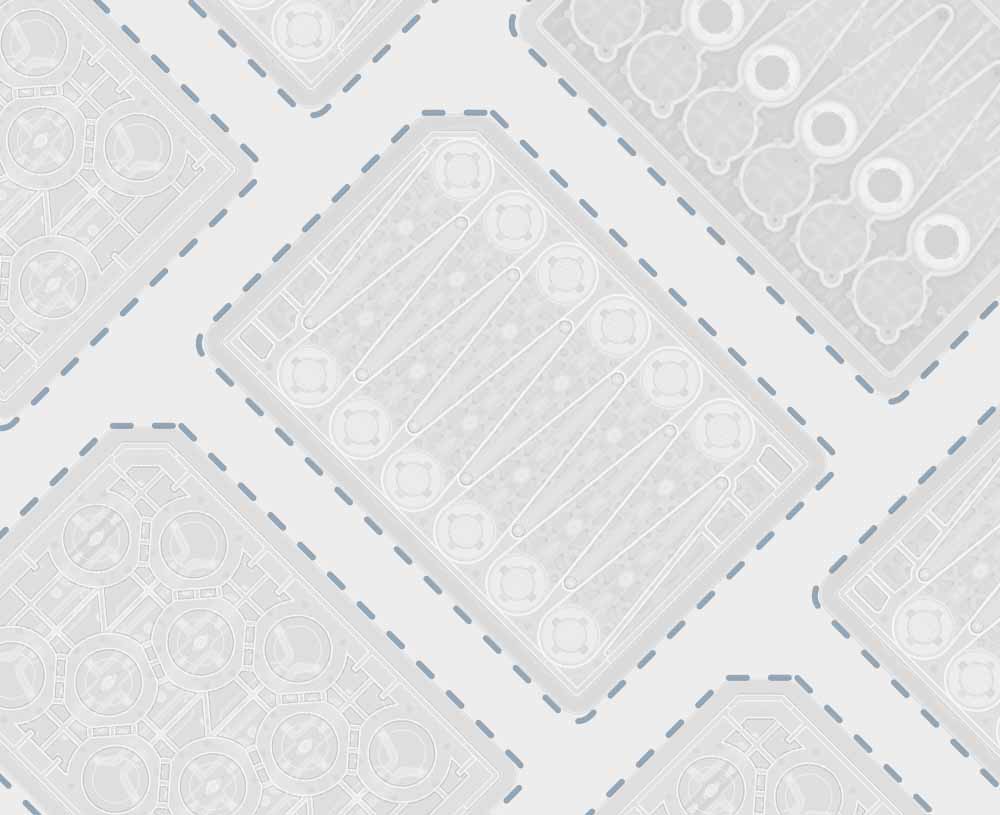

4. Bespoke consumables

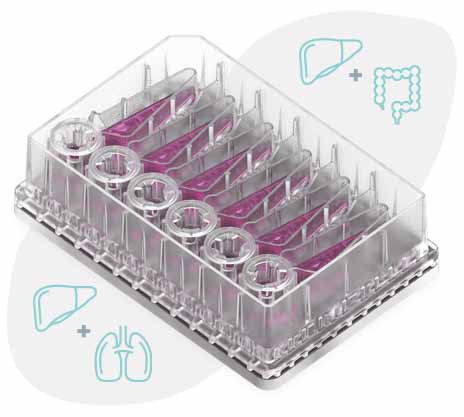

We don’t force the biology to match a generic chip

Since each organ and tissue has its own microenvironmental needs and requirements, our Multi-chip plates are optimized for biology and bespoke to organ/tissue type to bring human relevance to your projects. This is achieved using differing scaffold materials, geometries, extracellular matrix coatings and fluidic flow – pulsatile, or continuous.

Our Dual-organ plate meets the needs of individual barrier organs (such as the gut or lung) and the liver, while providing communication between them to recreate human bodily systems and processes.

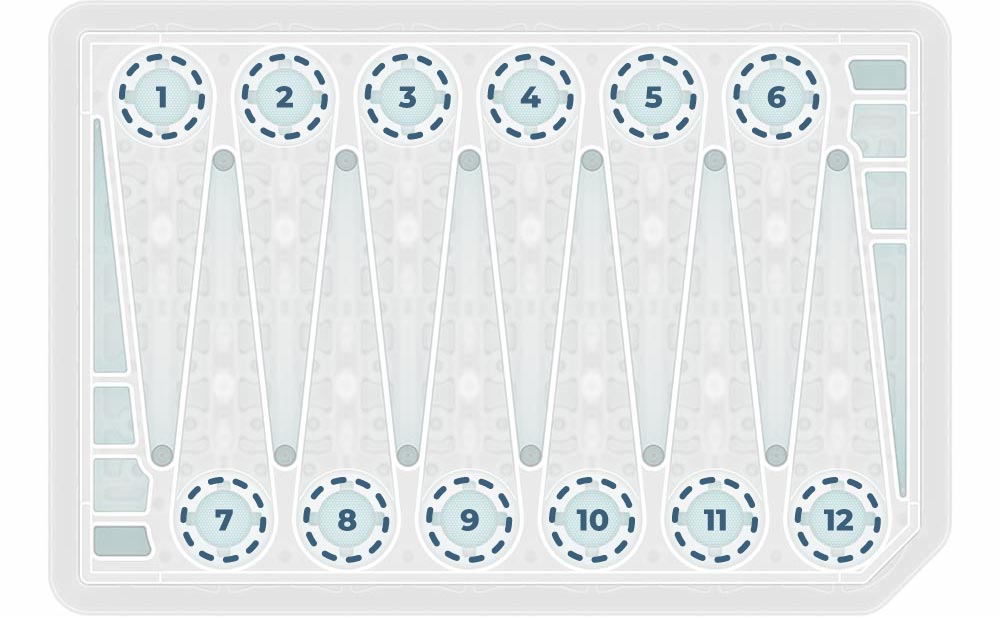

Liver-12 & -48 plates

Barrier plate

Dual-organ plate

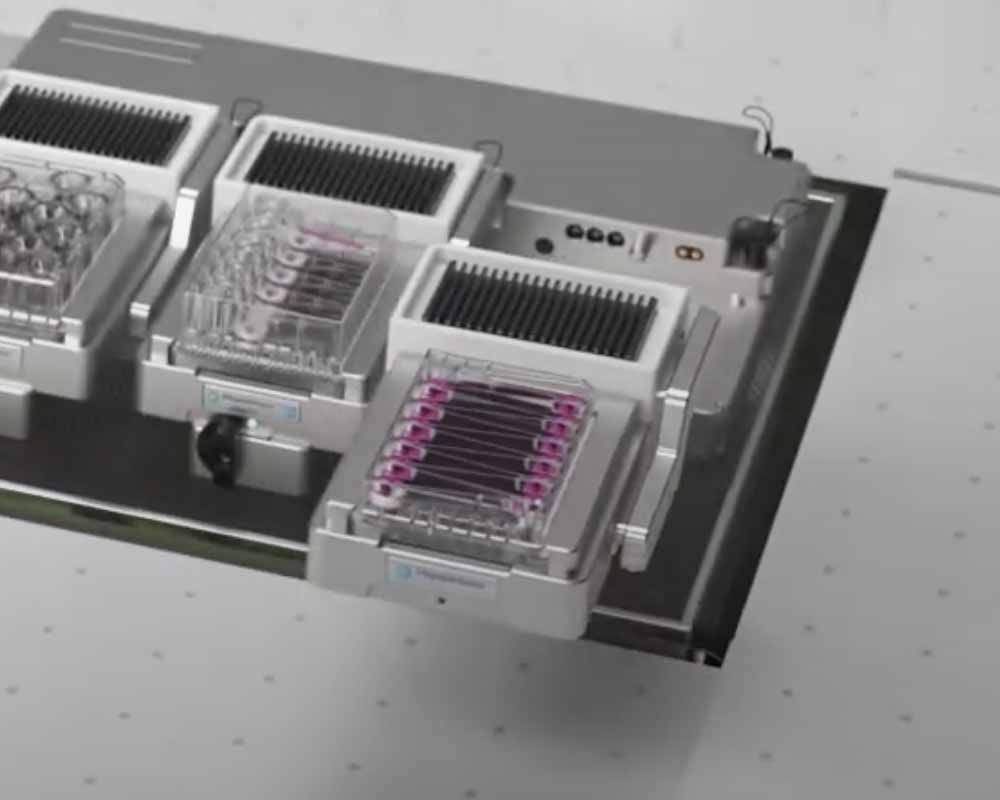

5. Multi-chip plate design

Rapid and accurate data generation

Our Multi-chip plate solution removes the laborious elements of traditional chips i.e., the installation and maintenance of tubing, and the requirement for expensive durable pumps and flow regulators.

Additionally, our design eliminates the need for durable element sterilization since the cells and their media remain contained within a pre-sterilized single-use consumable.

Their open architecture enables you to adapt our assays and models to match your context of use, or create your own.

PDMS-free

To minimize non-specific binding

Polydimethylsiloxane (PDMS) is frequently used within Organ-on-a-chip technology, however, its high non-specific binding properties pose a significant challenge and impact data accuracy.

PhysioMimix Multi-chip consumable plates are made of Cyclic Olefin Copolymer (COC) to minimize non-specific drug, or secreted cellular biomarker absorption.

When used in cell culture applications, COC offers one of the lowest nonspecific binding properties (van Midwoud et al, 2012 & Grindulis et al, 2025).

Familiar and standardized footprint

Enables rapid adoption

Our consumable plate design is based upon a standard, familiar SLAS-microplate footprint (previously known as an SBS footprint) to reduce adoption barriers, facilitate the use of common laboratory tools and provide compatibility with commonly utilized inserts (e.g. Transwell®).

A simple plate lid enables controlled gas exchange and the replenishment of atmospheric O2 (eliminating the need for a specific CO2 and O2 supply) whilst maintaining sterility.

Additionally, the lid provides easy access for adding drugs, supplements to induce disease, or to remove media for bioanalysis during an experiment.

Higher capacity, lower cost

Scalable throughput whilst maintaining data integrity

PhysioMimix Controller units can run up to six plates simultaneously; however, now that the benefits of Organ-on-a-chip technology have been realized, higher throughput solutions are in demand.

Our multi-chip plate-based approach permits scalability without a complete system redesign. Via careful miniaturization to maintain the same microenvironment and data quality, our Multi-chip Liver-48 plate quadruples the number of wells available within the same footprint as the Liver-12 plate whilst retaining data integrity. The Liver-48 plate provides up to four times the capacity (288 replicates/ run) of our Liver-12 plate and greater cost-effectiveness per replicate.

Science & Technology team

Members in the spotlight! Click a team member to read more about their role at CN Bio

Andy

Gareth

Ovi